If you recently shifted from an IT field to the Solar Industry then you might already be familiar with MTTD.

For Unbeknownst, Mean Time To Detect (MTTD), is a key performance indicator (KPI) for IT Incident Management and refers to the average amount of time it takes to discover an issue. It measures the period between the beginning of a system outage, service malfunction or any other revenue-generating activity, and the time it takes to identify this issue.

This is a very successful method in the IT Industry to reduce revenue loss by detecting and correcting issues in the shortest time possible.

Traditionally in solar, we rely on our onsite site team to take care of local maintenance and operations which takes time and the losses due to late detection add up over time.

From our knowledge from discussions with clients, it takes the site team 5-10 hours to detect issues manually, fixing it is a separate conversation and it takes more time depending on inventory, training of employees, SOPs etc.

Reducing MTTD Manually

I believe the current stage where the site team can identify in 5-6 hours is already optimized. Here are some more strategies to help minimize MTTD without relying on software:

Check for DELTA differences between two components of the same type, for example, two inverters with the same number of strings and loads connected. This requires the active participation of a human being to detect and report issues, with proper trained staff, generation loss can be reduced.

Implement Standard Operating Procedures (SOPs): Develop clear and concise SOPs for routine checks and issue identification. SOPs should cover different weather conditions, times of day, and specific areas of the solar power plant. Ensure that onsite teams are well-trained in following these procedures.

Use Monitoring Tools: While not software-dependent, basic monitoring tools like handheld infrared thermometers can help identify hotspots or anomalies in the panels. This can be a quick way to detect issues manually.

Training and Awareness: Invest in training programs for onsite teams to enhance their knowledge of common issues, troubleshooting techniques, and early detection methods. Awareness of potential problems can significantly reduce the time it takes to identify and address them.

Collaborative Communication: Establish clear lines of communication between onsite teams and management. Encourage reporting of any irregularities promptly. A well-coordinated communication system can help in faster issue escalation and resolution.

Historical Data Analysis: Keep a record of historical data and analyze it regularly. Look for patterns or deviations from the norm. This can help in predicting potential issues before they become critical.

Continuous Improvement: Establish a culture of continuous improvement. Regularly review incidents, their detection times, and resolutions. Use this information to refine processes and enhance the efficiency of manual detection methods.

Reducing MTTD with the help of Software

Let’s do a simple math,

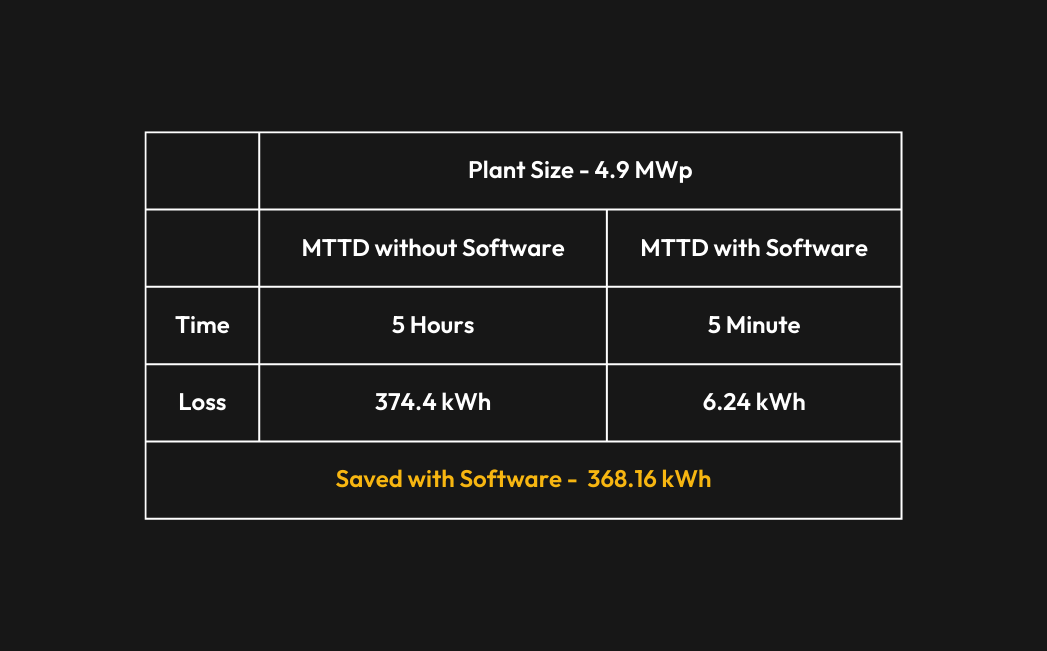

Let’s take one of the 4.9 MW DC sites on-boarded on FutrOS, It has:

1) 400 strings of 12.48 Kw DC load

Assume just 6 of 400 strings were down, taking avg 5 hours to detect, the losses till detection of generation would be without software:

- Losses in 5 hours:Total DC load = 400 strings 12.48 kW/string = 4992 kW Defective strings = 6 stringsLoss due to defective strings in 5 hours = 6 strings 12.48 kW/string * 5 hours = 374.4 kWh (kilowatt-hours)

Assume just 6 of 400 strings were down, taking 5 minutes to detect using software, the losses till detection of generation would be:

- Losses in 5 minutes:Loss per hour = 374.4 kWh / 5 hours = 74.88 kWhLoss in 5 minutes = (74.88 kWh / 60 minutes) * 5 minutes = 6.24 kWh

So, the losses in kilowatt-hours (kWh) would be 374.4 kWh over 5 hours and 6.24 kWh over 5 minutes.

That is 368 kWh saved at the strings level, with just a single tracking metric.

I believe that now we are on the same page in terms of understanding the importance of software, right?

The end rectification will be done by your site team only (In the next post, I will tell you how to optimize at this stage with the help of software), the software will assist your team detect and identifying the issues and components faster, thus reducing downtime and generation losses.

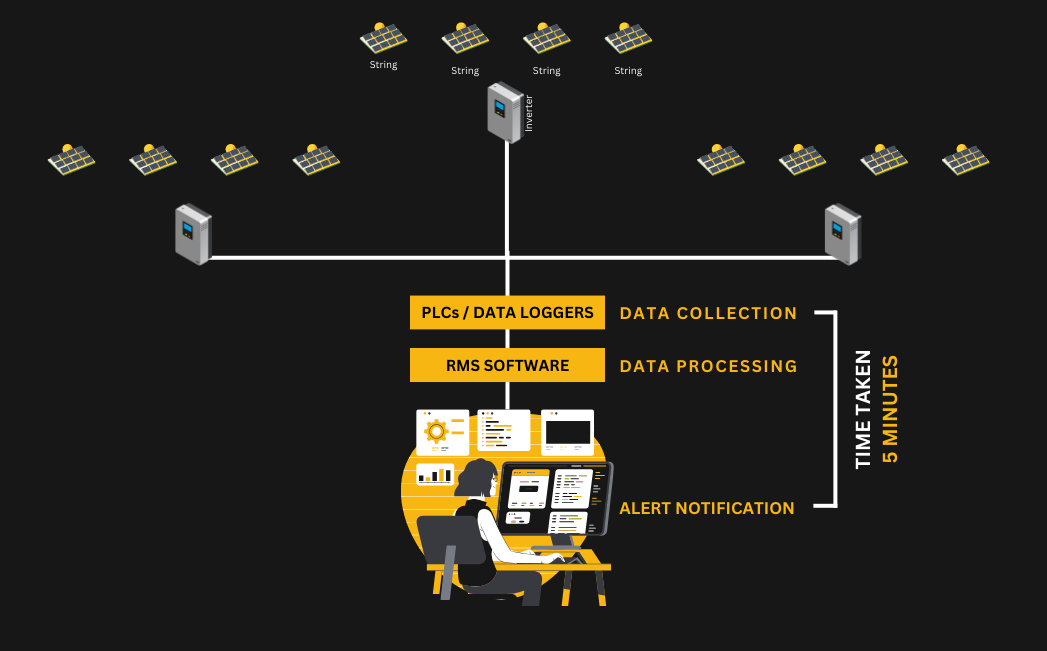

Mechanism of such Software:

Reducing Mean Time To Detect (MTTD) with the help of software in a solar power plant involves implementing advanced monitoring and analytics tools. Here are steps to optimize MTTD using software:

- Implement Solar Asset Monitoring Software: Utilize dedicated solar asset monitoring, control and analytics software. This type of software continuously monitors key parameters such as energy production, voltage, current, and temperature. It can quickly identify deviations from normal operating conditions.

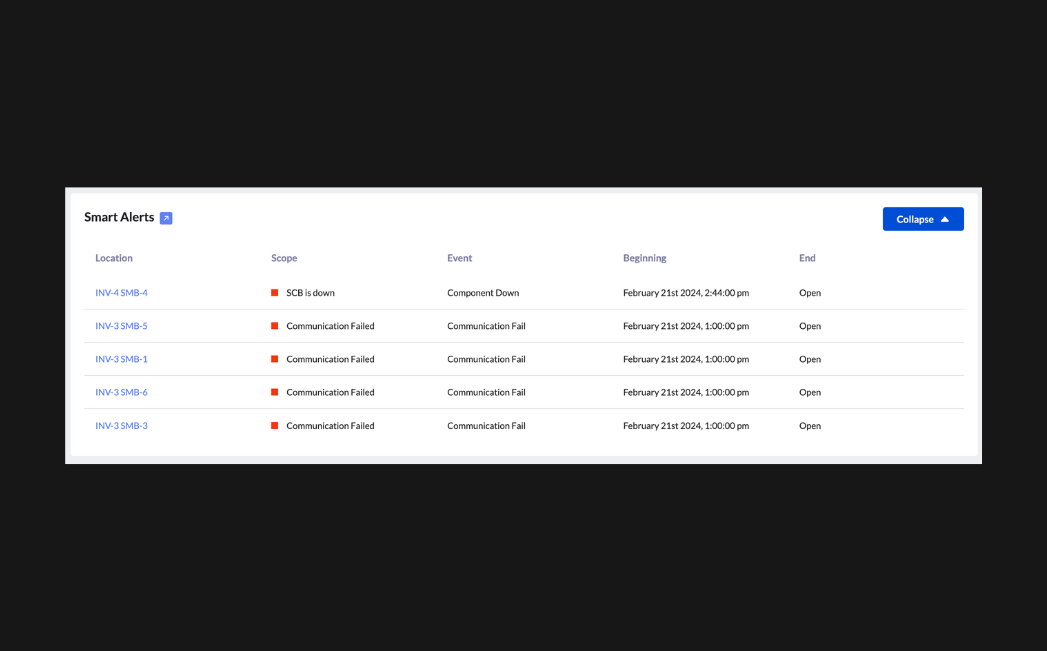

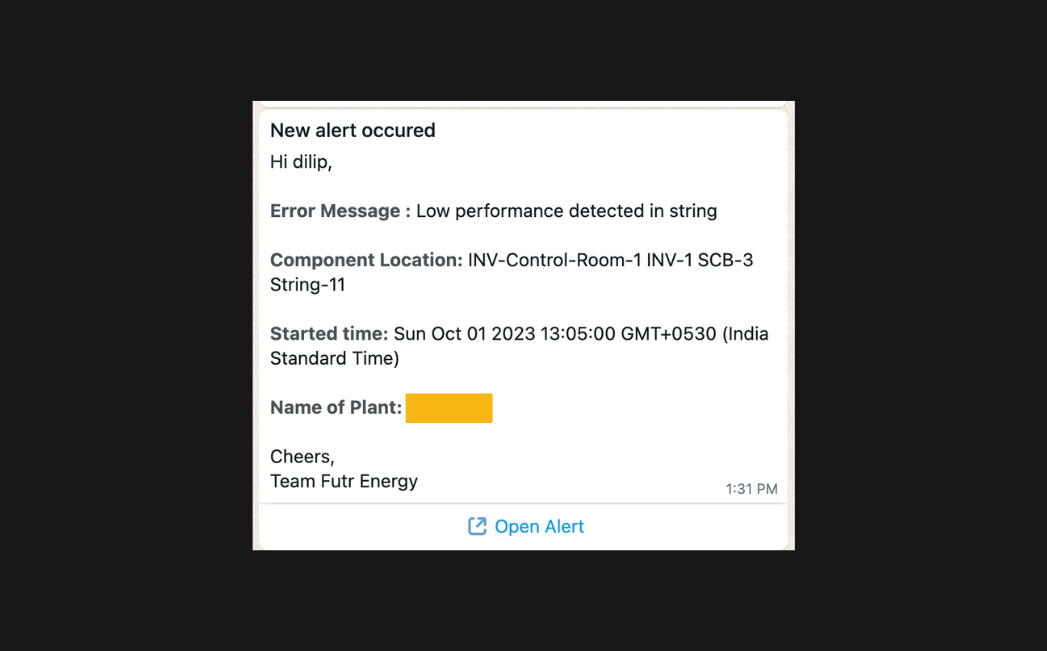

- Automated Alerts and Notifications: Configure the software to generate automated alerts and notifications for any abnormalities or issues detected. These alerts should be sent in real-time to the relevant personnel or monitoring team.

- Data Analytics and Machine Learning: Leverage data analytics and machine learning algorithms within the software. These tools can analyze historical data, identify patterns, and predict potential issues before they escalate. The software can continuously learn and adapt to the specific conditions of the solar power plant.

- Remote Monitoring: Implement remote monitoring capabilities, allowing the solar power plant to be monitored from a central location. This enables quick detection of issues without relying solely on onsite personnel.

- Integration with Weather Data: Integrate the software with real-time weather data. Weather conditions can impact solar panel performance, and integrating this information allows for better context when identifying issues. For instance, sudden cloud cover or heavy rain might lead to a temporary drop in energy production.

- Fault Localization: Develop software features that assist in localizing faults. Pinpointing the exact location of an issue, whether it’s a malfunctioning panel or a faulty connection, can significantly reduce the time needed for onsite diagnosis and repairs.

- Mobile Applications for Field Teams: Provide field teams with mobile applications connected to the monitoring software. This allows them to receive alerts and diagnostic information on their devices, enabling quicker response times when attending to issues on-site.

- Historical Performance Analysis: Use the software to conduct in-depth analysis of historical performance data. This analysis can uncover trends and recurring issues, guiding proactive measures to prevent future problems.

- Collaboration Platforms: Implement collaboration platforms within the software that facilitate communication between onsite teams, maintenance crews, and management. This ensures a coordinated response to detected issues.

By integrating sophisticated software solutions with solar power plant operations, you can significantly reduce MTTD, leading to quicker issue detection, faster response times, and ultimately minimizing downtime and generation losses.

End output of using Remote Monitoring Software:

Let’s take FutrLogger‘s RMS as an example,

This generates alerts on your desktop between 1-5 minutes based on the frequency set,

But for this, you need to be on your desktop to keep checking the alerts tab, so we have gone a step forward to reduce MTTD by sending alerts to your WhatsApp number directly.

Since as Indians, we are most active on WhatsApp, sending alerts directly to WhatsApp reduces MTTDs by a further margin and it gives flexibility to the site team to be aware of any problems anytime, anywhere. It doesn’t require the active participation of a site person which reduces human error margin.

So, this was just one of the ways to increase the Performance Ratio (PR) at solar power plants, there are more ways that I might talk about it in future.

If I am new to you,

Hi, I am Dilip and I am currently building FutrLogger, an IoT-SaaS powered Monitoring, Control and Analytics Platform for Renewable Energy.

Since entering the market we’re replacing major competitors and becoming clients first choice. We empower solar asset owners, operators, and investors to effortlessly monitor performance, anticipate and prevent failures, and ensure proactive maintenance of valuable assets, providing real-time insights and predictive analytics.

Tschüss! (That’s bye in German)